Welcome to Matrix Tool

Matrix Tool, Inc., founded in 1972, is a full-service Thermoplastic Injection Mold Building and Molding company serving the high precision Automotive, Computer, Electronics, Metal Injection Mold (MIM), and Pharmaceutical/Medical Industries — all under one roof.

Overall, Matrix is a world-class supplier with excellent technical support, technology and business processes. Matrix is a tremendous partner to have in our supply chain.

Transfer Tooling & Reshoring Services

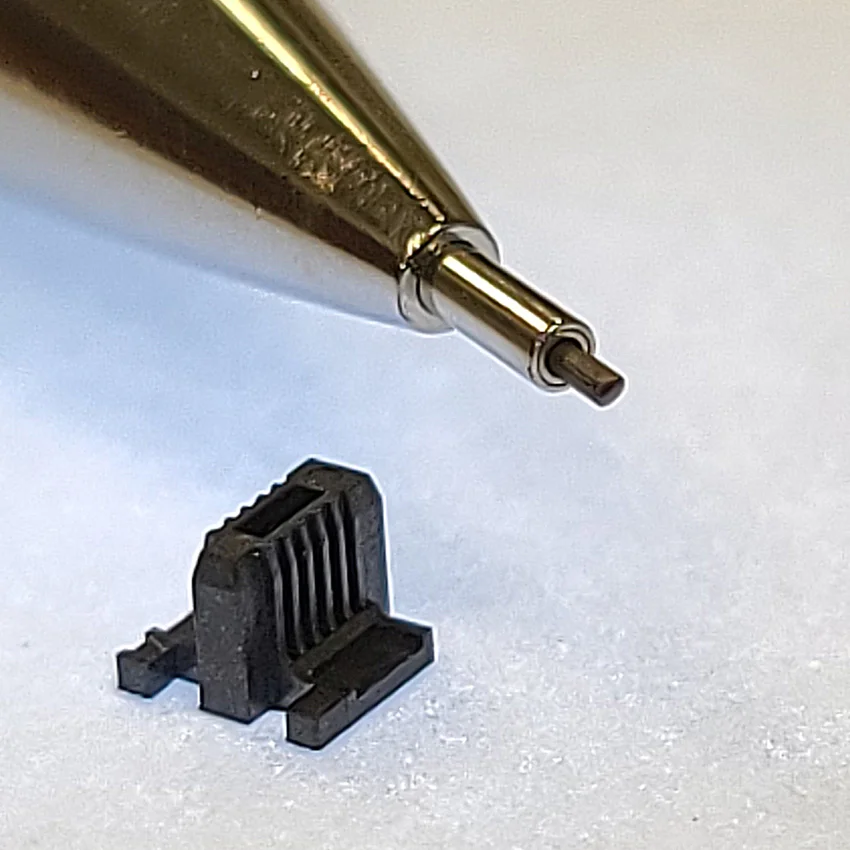

Learn MoreMicro Injection Molding

Learn MorePrecision Mold Making

Learn MoreThin Wall Injection Molding

Learn MoreThe Matrix Advantage

Matrix is an engineering driven manufacturer of custom plastic injection molded products. We are experts in producing high precision micro and standard-sized complex parts. These include electrical connectors, computer connectors, automotive under the hood components, or any other tight tolerance molded part requiring a wide range of engineering grade thermoplastics.

With over a dozen degreed plastics and mechanical engineers on staff, we have a deep bandwidth of engineering talent. They help to drive innovation and precision through a systematic approach in every area of the company. That innovation results in much lower cycle times through our advanced Small Part Micro Molding initiatives.

Full Service Warranty

We build tooling and mold plastic parts of the highest quality ranging from single cavity prototypes to 64-cavity high volume production molds. From precision mold design and mold construction, through sampling, tool debug, approval and production, Matrix Tool provides our customers a complete in-house plastic project solution. That solution comes with a Life of Program mold warranty for any production tool we design, build and remains at Matrix Tool for production. Contact Us for more details.

Help When You Need It Most

As part of the RFQ process, Matrix provides engineering solutions for your challenging molded products. Whether you have a preliminary part print or a fully detailed 3D model, we will evaluate the product design and offer alternative suggestions to minimize risk and waste, factors that lead to more cost-effective manufacturing. We’ll quote what you ask for, but we’re not afraid to offer innovative alternatives as well. We gladly give this support as a full-service supplier. Our track record of success speaks for itself.

Trusted Global Partner

Matrix is dedicated to delivering innovative tooling and molding solutions that consistently meet the highest industry standards. Our commitment to excellence extends beyond manufacturing – we prioritize customer satisfaction, on-time delivery, and continuous improvement, making us the preferred choice for companies seeking a reliable and forward thinking manufacturing partner.

While nearly anyone should be able to succeed with simple parts, we regularly excel when presented with the most difficult of challenges. Partnering with Matrix provides a steady return on your investment – with less worries too. We just take care of business and actively work to present solutions, and not questions, to new challenges when they arise. Test the expertise and influence Matrix can have on your bottom line by leveraging us as your company’s truly strategic manufacturing supplier and partner.

Turnkey Injection Molding Solutions Provider

Every injection molder will claim to have the best employees, equipment, and quality systems. Matrix has all that for sure, but we take injection molding services to the next level.

We provide seamless, end-to-end solutions, overseeing every phase of the manufacturing process—from mold design and engineering to mold construction, precision molding, and rigorous quality assurance—followed by reliable deliveries of high-quality, finished components. Our entire facility is equipped with state-of-the-art equipment, ensuring precision and efficiency at every stage of the process. From concept to delivery, we handle it all with unmatched expertise and attention to detail.

Precision Injection Molding Technology

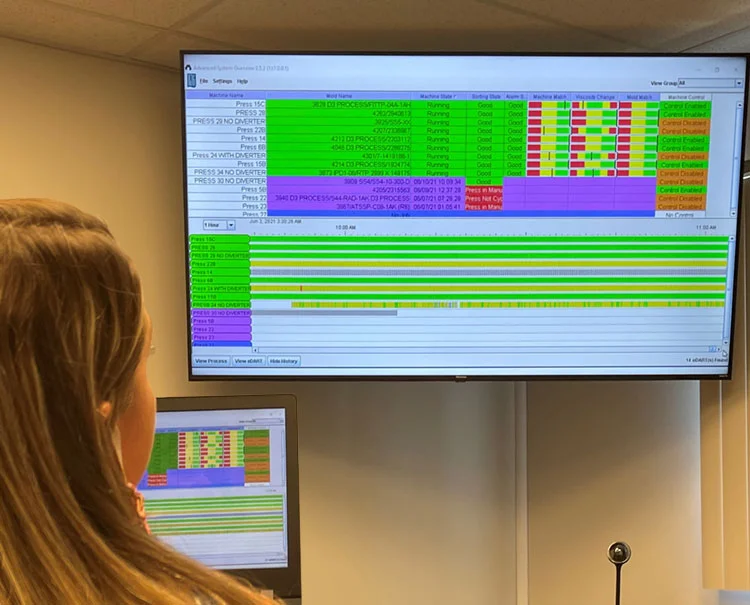

With (24) conventional injection molding presses and (17) high-speed micro injection molding presses, Matrix Tool has a broad offering of injection molding machines ranging from 20 Tons to 237 Tons of clamping force. We offer true, closed-loop, decoupled 3 plastic injection molding processing with real-time monitoring for additional control. See our Scientific Molding Page for more information.

A Difference That Matters

What separates Matrix Tool is our stand-alone department of plastics engineers, toolmakers and technicians who provide 24-hour tool evaluation, sampling/de-bug, repair and changeover services for the molding department. This capability is rare among injection molding suppliers in the United States or elsewhere. The results are extremely high quality and customer service scores.

We recognize that the quality of our products has a powerful impact on our customer’s operation and reputation. That is why Matrix Tool has adopted mold cavity pressure transducer technology, or RJG technology, throughout the entire facility to ensure the highest quality standards. Our robust Quality Management System wraps around every aspect of the manufacturing process.

We invite you to spend a few minutes browsing our website to learn more about Matrix Tool. Find out the difference an engineering focused, full-service custom injection molding company can make for your next project.

We hope you enjoy your visit and look forward to hearing from you!